Have you ever wondered how many stitches there are on a baseball? Why the stitching is in the shape it is? What exactly a baseball is made of or how exactly it is made? We are going to “unravel” exactly how the baseball is made.

History of the Baseball

The game of baseball has changed a lot since the 1800s and so has the baseball itself. The modern-day baseball is completely different from its early origins.

The very first baseballs were handmade. It was customary for the first team to provide the baseballs so teams would usually choose a ball that suited their team’s style of play.

Handmade baseballs started with a solid center, sometimes a rock or melted rubber. Then, string or cloth was wound tightly around the center. Finally, a cover was added that usually was made of leather and stitching was added to hold it all together.

In the 1850s baseball became more organized and teams began discussing standardizing the baseball. Meetings were held to discuss weight, dimensions, and construction methods.

The standard baseball changed a lot between 1854 and 1871. The standard weight changed anywhere from 5 ½ ounces to up to 6 ¼ ounces.

Modern MLB rules now specify that the baseball center be made up of a cork and rubber core. The ball should measure between 9 and 9 ¼ inches in circumference and the ball must weigh between 5 and 5 ¼ ounces.

How a Modern Baseball is Made

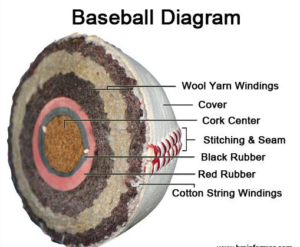

There are 3 basic parts to every baseball: a cushioned cork at the center, a poly/cotton midsection, and a cowhide leather cover.

The center of the ball is a cushion cork that has two shells of black rubber molded to it, followed by a thin layer of red rubber.

Then, a thin layer of rubber cement is added to hold the yarn in place. Several different layers of yarn and rubber cement are wrapped around the ball until the circumference is 8 7/8 inches and the weight is 4 3/8 ounces.

Finally, the cover is added. The cover is made of cowhide and consists of two figure-eight shaped pieces that are first stapled to the ball and then stitched together by hand.

How Many Stitches Are on a Baseball?

The stitching process of the baseball is the most intricate and time-consuming part of baseball creation. Each baseball is hand-stitched with a total of 108 red thread, double stitches. The stitching process of the baseball uses a total of 88 inches of waxed red thread and the entire process averages between 13 to 14 minutes for every baseball made.

The horseshoe-shaped stitching on the ball allows pitchers to throw balls with better movement based on their finger placement along the seams. Learn more about the different types of baseball pitches and their pitch grips.

After the stitching is completed, the staples holding the cover on are removed. The ball is then inspected and put through a rolling machine for 15 seconds to help eliminate any raised stitches.

Several attempts have been made to automate the baseball stitching process, but none have succeeded. Automated machines have lacked the ability to start and stop stitching without assistance. The tested machines have also been unable to vary the tension of the stitching which is necessary for the two coverings to fit securely without tearing.

Once a baseball is inspected, weighed, and graded for appearance. Acceptable balls are stamped with the manufacturer’s trademark and the league designation.

The baseball has not changed much in several decades besides some minor changes to the materials used. Some years, such as in 2019, players and fans have accused the league of a ‘juiced’ ball.

It is unlikely that the baseball will change anytime soon. There is a delicate balance between pitching and hitting and the current ball has been tested and proven to give us the game that we love today.

Learn more interesting baseball facts on our FAQ page.

Leave a Reply

You must be logged in to post a comment.